14way IP40 Dustproof Plastic Circuit Breaker Residential Distribution Board Distribution Box

Application

BE series is used for indoor power distribution mainly for lighting control for residential and commercial buildings.

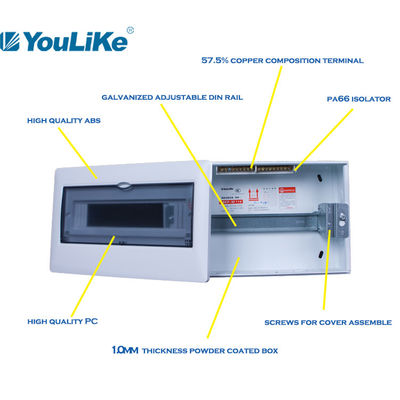

1. Din rail to be galvanized steel, with horizontal & vertical adjustment funtion.

2. Brass terminals (1pcs earthing & 1pcs neutral) is with 57.5% composition.

3. Stainless earthing bolts with warning label.

4. Reinforced structure design to allow higher tensile strength of plastic cover.

5. Metal metal spring plate to provide extra service life of plastic hinges.

Product Characteristics

1. Box to be available for powder coated steel, with 1.0mm thickness.

2. Cover frame to be available for HIPS material.

3. Door to be available for HIPS, both white door and golden door.

4. All plastic parts are without specific flame retardant and qualified to pass incandescent wire test at 650℃.

5. Pastic can be customized to flame retardant (grade V1~V0 depends on material choosed).

6. High purity zero line flow discharge.

Company Profile

1.YOULIKE founded in 2005, it specializes in the production, R & D and sales of indoor distribution box, multi-media box and power cabinet.

2. The product design takes safety as the core concept, and has obtained 33 design patents, 20 utility model patents and 2 invention patents.

3. It has served 1350 leading real estate companies and 1600 panel builder.

4. In 2015, the sales revenue will exceed 100 million, and the annual box sales volume will reach 3 million pieces.

5. After 16 years of development and customer support, it has also gained a certain reputation.

Specifications of BE series, Surface

| Model |

Way |

Cover size |

Box size |

Terminals

|

Knockouts |

| L*H*T (mm) |

L*W*D*T(mm) |

size(mm) |

PE |

N |

one side qty |

| BEP-M 104 |

4way |

168×164×16.5(22.0) |

168×164×80×1.0 |

6*10 |

4 |

5 |

2 |

| BEP-M 107 |

7way |

222×214×18.5(24.0) |

221×213×80×1.0 |

6*10 |

|

7 |

6 |

| BEP-M 110 |

10way |

276×214×18.5(24.0) |

275×213×80×1.0 |

6*10 |

8 |

7 |

7 |

| BEP-M 112 |

12way |

312×214×18.5(24.0) |

311×213×80×1.0 |

6*10 |

8 |

9 |

8 |

| BEP-M 114 |

14way |

348×214×18.5(24.0) |

347×213×80×1.0 |

6*10 |

11 |

10 |

9 |

| BEP-M 116 |

16way |

384×214×18.5(24.0) |

383×213×80×1.0 |

6*10 |

11 |

10 |

9 |

| BEP-M 118 |

18way |

420×214×18.5(24.0) |

419×213×80×1.0 |

6*10 |

13 |

12 |

10 |

| BEP-M 120 |

20way |

456×214×18.5(24.0) |

455×213×80×1.0 |

6*10 |

13 |

12 |

12 |

| BEP-M 228 |

28way |

351×381×19(26.5) |

350×380×95×1.2 |

6.4*12 |

16 |

15 |

9 |

| BEP-M 240 |

40way |

459×381×19(26.5) |

458×380×95×1.2 |

6.4*12 |

18 |

17 |

12 |

Workshop Demonstration

Packing

| Model |

Carton size |

Volume/ctn |

Pcs/ctn |

Calculated weight(kgs/ctn) |

| mm |

m³ |

net weight |

gross weight |

| BEP-M 104 |

525*215*355 |

0.0401 |

10 |

9.58 |

|

| BEP-M 107 |

525*290*455 |

0.0693 |

10 |

14.66 |

|

| BEP-M 110 |

525*345*455 |

0.0825 |

10 |

17.10 |

|

| BEP-M 112 |

525*235*405 |

0.0450 |

5 |

9.25 |

|

| BEP-M 114 |

525*235*440 |

0.0543 |

5 |

10.20 |

|

| BEP-M 116 |

525*235*495 |

0.0611 |

5 |

11.65 |

|

| BEP-M 118 |

545*240*280 |

0.0367 |

2 |

6.70 |

|

| BEP-M 120 |

460*135*385 |

0.0239 |

1 |

3.60 |

|

| BEP-M 228 |

455*160*425 |

0.0310 |

1 |

4.05 |

|

| BEP-M 240 |

510*160*460 |

0.0376 |

1 |

4.75 |

|

Neutral carton packing Our style carton

Remarks: #1. Both customized color box or neutral box is available.

#2. In case customized color box is required, there is a MOQ≥1000pcs/each size.

#3. Customized logo print on product is available with no additional charge.

Attention Points

1. When the bottom box is embedded with concrete and poured on site, the bottom box needs to be supported up and down, left and right to prevent the bottom box from deformation.

2. During the installation of the upper wall of the bottom box, it is forbidden to block the threaded hole on the right plate with cement mortar.

3. The maximum bearing torque of the grounding screw on the bottom box is 20n. m.

4. It is recommended to install the support panel after the wall is puttying.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!